On Line Safety Relief Valve Testing

Control Valve Services Ltd. Teson II system delivers safe and accurate pressure on line safety relief valve testing – without operational disruption to the plant.

On Line Testing of pressure relief valves enable you to ensure that every safety relief valve is operating at peak efficiency and meeting relevant safety obligations; key factors when it comes to maintaining plant productivity, safety and profitability.

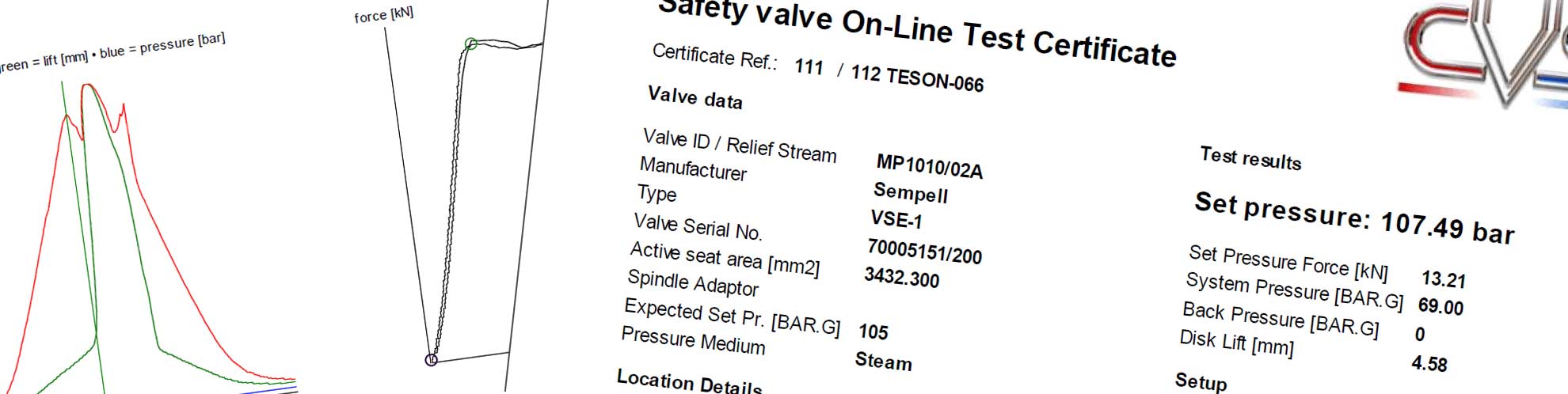

Control Valve Services Teson II system identifies safety relief valves in need of adjustment or full service. The tests are performed in-situ, on-line and under normal operating conditions. The result is a certifiable process approved by all main insurance companies that allows correctly performing valves to remain in service for longer periods, and identifies valves that do not meet the correct performance criteria so that they can be scheduled for maintenance at the next available opportunity.

Other key benefits:

• No plant downtime required

• Minimal loss of plant pressure and line medium during Control Valve Services Teson II On Line Safety Relief Valve Testing

• On Line Safety relief valve testing significantly reduces the time required to commission the plant after shutdown

• On Line Safety relief valve testing provides detailed analysis including electronic reports and advice on faults or performance issues

• The majority of spring loaded safety relief valves and pilot operated valves can be on line tested

• TÜV & DNV approved system

• On Line Safety relief valve testing can be adapted to suit most customer safety relief valve testing requirements

• Efficient digital management of test data, including settings and results

• Removes the need for temperature compensation for set pressure as the test is executed at actual site operating conditions (mandatory for bench test)

• Safety Relief Valve is free to function normally throughout the on line testing operation

• Online (hot) and offline (cold) testing capability