Control Valve Diagnostics

CVS were first to market in the UK with control valve diagnostics technology; the benefits of adopting control valve condition monitoring are significant. Adopting control valve diagnostics as part of your maintenance regime are significant both financially and environmentally, by ensuring your control valves are calibrated to a laboratory standard thus optimising control valve performance to improve plant efficiency and reliability.

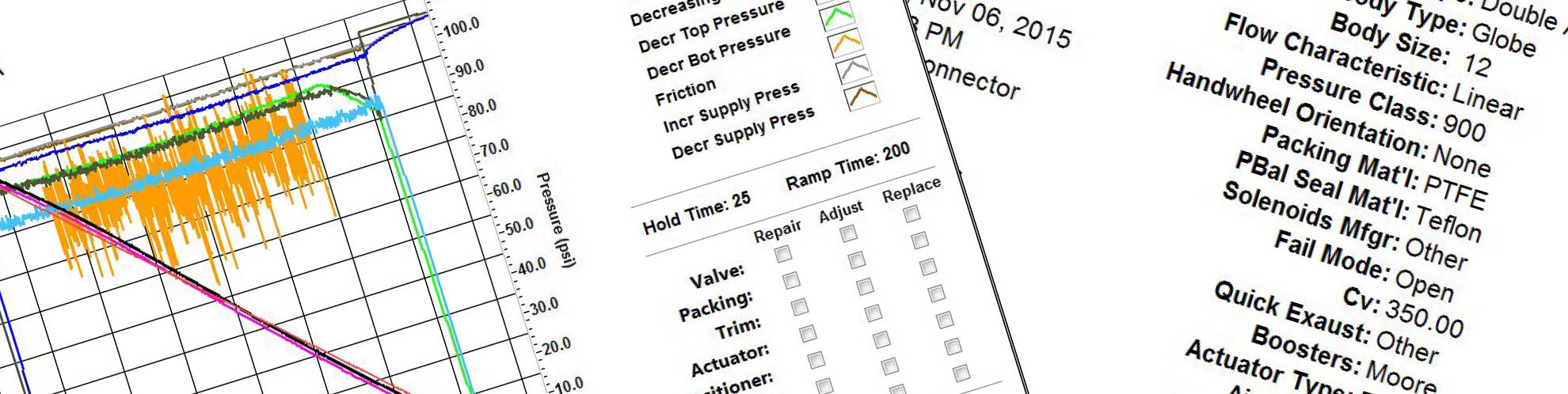

Our systems monitor both mechanical condition of the valve and instrument condition of actuators, positioners, associated instrumentation and costly pneumatic leakages to atmosphere. This full spectrum measurement provides you with a full picture of your control valve assets condition. Having this knowledge simplifies your decision making for control valve maintenance regimes and outage planning to ensure maintenance work performed is both effective and measurable.

Control Valve Services are the UK market leaders providing immediate results for our clients utilising our control valve diagnostics technology. CVS have a team of highly trained technicians operating throughout the UK & Ireland helping our clients make correct decisions and in turn reducing maintenance expenditure by quickly drilling down to the heart of the defect.

Control Valve Diagnostics are revolutionising the process & utility industries maintenance programmes…

Understand your plant profile:

- P redict maintenance requirements

- R educe unnecessary expenditure

- O ptimise your maintenance budget

- F urther increase overall plant efficiency

- I mprove control valve reliability

- L imit plant downtime

- E nsure control valve efficiency

Reduce your costs…..Protect your Control Valve Assets!

Predictive Maintenance

Adopting a control valve diagnostics programme allows plant operatives to understand the true condition of each control valve by:

- Predicting exact maintenance requirements

- Significantly reducing maintenance expenditure

- Increasing overall plant efficiency

Reduce Spares Expenditure

Historical practice has been to inspect valves due to routine maintenance procedures, this practice is evolving, using control valve diagnostics; allowing the plant operator to:

- Understand the exact maintenance requirements of each control valve

- Monitor the life cycle of each control valve

- Develop a control valve specific maintenance regime

- Safeguard control valve maintenance budgets

- This level of understanding reduces the lifetime cost of ownership utilising a more effective level of condition monitoring, significantly reducing aftermarket spares expenditure.

Environmental Benefits

Imagine how much wasted energy there is globally due to defective leaking control valves and associated instrumentation. Embracing a control valve diagnostics programme will help optimise your plants efficiency and provides you with more than just financial rewards…